Jagora don Ƙarfin Ƙirƙiri a cikin Topfeel

Ƙarfin samarwa alama ce mai mahimmanci ga kowane ƙirar ƙirar ƙira.

Topfeel yana kan gaba wajen ba da shawarar falsafar kasuwanci na "maganin marufi na kwaskwarima" don magance matsalolin abokan ciniki a cikin zaɓin nau'in marufi, ƙira, samarwa, da daidaitawa jerin. Yin amfani da ci gaba da ƙirƙira fasaha da albarkatun samar da ƙira, da gaske mun fahimci haɗakar hoton alamar abokin ciniki da ra'ayin alama.

Ci gaban ƙira da masana'anta

Molds ne daban-daban kyawon tsayuwa da kayan aikin da ake amfani da su a masana'antu samar da allura gyare-gyare, busa gyare-gyare, extrusion, mutu-simintin gyaran kafa ko ƙirƙira kafa, smelting, stamping da sauran hanyoyin da ake bukata kayayyakin. A takaice dai, mold kayan aiki ne da ake amfani da shi don yin abubuwa masu siffa. Wannan kayan aiki yana kunshe da sassa daban-daban, kuma nau'i-nau'i daban-daban sun hada da sassa daban-daban.

Ƙirƙirar ƙira:

1. Cavity: Ana buƙatar gogewa ta hannu, ta amfani da S136 karfe tare da babban taurin 42-56.

2. Mold tushe: low hardness, sauki karce

3. Punch: bangaren da ke samar da siffar kwalba.

4. Mutuwa:

① Yana da alaƙa da rayuwar ƙwayar cuta da lokacin samarwa;

②Maɗaukakin buƙatu akan madaidaicin rami

5. Tsarin slider: Hagu da dama na lalata, samfurin zai sami layin rabuwa, wanda akasari ana amfani dashi don kwalabe na musamman da kwalba waɗanda ke da wuya a lalata.

Sauran kayan aiki

Niƙa

• Mafi madaidaicin kayan aiki a cikin tsarin samar da mold.

• Ƙananan grinder: na iya aiwatar da sassa na zagaye da murabba'ai, yi amfani da barasa na masana'antu don kwantar da hankali, aikin hannu.

• Large grinder: kawai rike square kyawon tsayuwa, yafi rike dama kwana na mold tushe; emulsified man sanyaya; inji aiki.

Latsa rami

Injin hakowa: sarrafa ramin dunƙule na mold.

Milling Machine: m machining dunƙule ramukan, kuma yana iya yanke kyawon tsayuwa.

Na'ura ta atomatik ta atomatik: sarrafa zaren ƙirar ƙira

①Hakoran hakoran dunƙule suna da kyau

②A tsaye na zaren yana da kyau

Kayan aikin inji na al'ada

- Gudanar da gyare-gyaren zagaye, kayan aikin da aka yi amfani da shi shine tungsten karfe, tungsten karfe high taurin, ƙananan lalacewa da tsagewar da ake amfani da su, ƙarfin yankan ƙarfi, amma laushi mai laushi, mai rauni.

- Galibi ana amfani da su don naushi, cavities da sauran sassan sassa na zagaye.

Kayan aikin injin CNC

- molds. Yi amfani da abin yankan carbide tungsten, yi amfani da man emulsified don sanyaya.

- Lokacin yankan, daidaita duk kayan aikin (counterblade)

Tsarin samarwa da haɗuwa

Tsarin taro na tushen famfo

Piston sanda, spring, kananan fistan, piston wurin zama, murfin, bawul farantin, famfo jiki.

Tsarin taro na shugaban famfo

Duba-wurin rarraba-latsa famfo core-latsa famfo shugaban famfo.

Tsarin taro na bambaro

Ciyarwar abu-mold (bututu forming) -saitin ruwa kula da bututu diamita-ruwa hanya-kanti bambaro.

Tsarin taro na kwalban mara iska

Ƙara man siliki a cikin kwalabe-piston-kafada hannun riga-fitar kwalaben-gwajin iska.

Tsarin samar da sana'a

Fesa

Aiwatar da fenti a ko'ina a saman samfurin don cimma sakamakon da ake so.

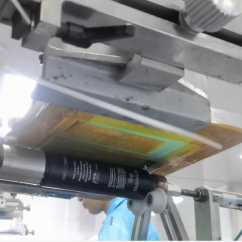

Buga allo

Buga akan allo don samar da hoto.

Zafafan hatimi

Buga rubutu da alamu akan takarda mai zafi mai zafi a ƙarƙashin babban zafin jiki da matsa lamba.

Lakabi

Yi amfani da injin don yiwa kwalabe lakabin.

Gwajin ingancin samfur

Tsarin dubawa

Albarkatun kasa

Production

Marufi

Kammala kayayyakin

Matsayin dubawa

➽ Gwajin jujjuyawaTorque = diamita na bayanan zaren / 2 (wanda ya cancanta a cikin kewayon ƙari ko ragi 1)

➽Gwajin danko: CP (naúrar), mafi kauri kayan aikin gwajin shine, ƙarami, kuma mafi ƙarancin kayan gwajin shine, mafi girma.

➽Gwajin fitila mai launi biyu: gwajin ƙudurin katin launi na ƙasa da ƙasa, tushen hasken gama gari na masana'antar D65

➽Gwajin hoton gani: Misali, idan sakamakon gwajin dome ya wuce 0.05 mm, gazawar ne, wato nakasawa ko kaurin bango mara daidaituwa.

➽karya gwajin: Ma'auni yana cikin 0.3mm.

➽Gwajin abin nadi: 1 samfur + 4 gwaje-gwajen dunƙule, babu takardar da ke fadowa.

➽Gwajin zafi mai girma da ƙananan: Gwajin zafi mai zafi shine digiri 50, gwajin ƙarancin zafin jiki shine -15 digiri, gwajin zafi shine digiri 30-80, lokacin gwajin shine awa 48.

➽Gwajin juriya na abrasion: Ma'aunin gwajin shine sau 30 a cikin minti daya, juzu'i 40 baya da gaba, da nauyin 500g.

➽Gwajin taurin: Kawai takardar gaskets za a iya gwada, naúrar ne HC, sauran taurin kyawon tsayuwa da matsayin da kuma tsarin kulawa.

➽Gwajin juriyar yanayin ultraviolet: Don auna tsufa, musamman don ganin canza launi da aiwatar da zubar da ciki. Awanni 24 na gwaji yayi daidai da shekaru 2 a ƙarƙashin yanayin al'ada.