Phau Ntawv Qhia Txog Kev Muaj Peev Xwm Ntau Lawm hauv Topfeel

Kev muaj peev xwm ntau lawm yog qhov taw qhia tseem ceeb rau txhua qhov chaw tsim khoom npaj tsim khoom.

Topfeel ua tus thawj coj hauv kev tawm tswv yim kev lag luam ntawm "kev daws teeb meem ntim tshuaj pleev ib ce" los daws cov neeg siv khoom cov teeb meem hauv kev ntim hom xaiv, tsim, tsim khoom, thiab sib txuam ua ke. Siv cov cuab yeej thev naus laus zis txuas ntxiv thiab cov peev txheej tsim pwm, peb tau pom tseeb tias kev koom ua ke ntawm cov neeg siv khoom lag luam cov duab thiab lub tswv yim hom.

Pwm txoj kev loj hlob thiab kev tsim khoom

Pwm yog ntau yam pwm thiab cov cuab yeej siv hauv kev tsim khoom rau kev txhaj tshuaj molding, tshuab moulding, extrusion, tuag-casting los yog forging forming, smelting, stamping thiab lwm txoj kev kom tau txais cov khoom tsim nyog. Hauv luv luv, pwm yog ib qho cuab yeej siv los ua cov khoom zoo li tus. Cov cuab yeej no yog tsim los ntawm ntau qhov chaw, thiab cov pwm sib txawv yog tsim los ntawm cov khoom sib txawv.

Pwm muaj pes tsawg leeg:

1. Cavity: phau ntawv polishing yog yuav tsum tau, siv S136 steel nrog lub siab hardness ntawm 42-56.

2. Pwm puag: tsawg hardness, yooj yim rau khawb

3. Punch: qhov uas ua rau lub raj mis zoo.

4. Tuag Core:

① Nws muaj feem xyuam rau lub neej ntawm pwm thiab lub sijhawm tsim khoom;

② Cov kev xav tau siab heev ntawm kab noj hniav precision

5. Slider qauv: Sab laug thiab txoj cai demoulding, cov khoom yuav muaj ib txoj kab sib cais, uas feem ntau yog siv rau cov fwj tshwj xeeb thiab cov hub uas nyuaj rau demould.

Lwm yam khoom siv

Grinder

• Cov cuab yeej siv tau zoo tshaj plaws hauv cov txheej txheem tsim pwm tag nrho.

• Me me grinder: tuaj yeem ua cov pwm puag ncig thiab square, siv cov cawv cawv kom txias, kev tuav haujlwm.

• Loj grinder: tsuas yog tuav square pwm, feem ntau yog tuav lub kaum sab xis ntawm pwm puag; emulsified roj txias; tshuab ua haujlwm.

Laum xovxwm

Drilling tshuab: ua cov ntsia hlau qhov ntawm pwm.

Milling tshuab: ntxhib machining ntsia hlau qhov, thiab tuaj yeem txiav pwm.

Tsis siv neeg tapping tshuab: xov ua cov pwm

① Cov hniav ntawm cov hniav ntsia hlau yog huv si

② Lub verticality ntawm cov xov yog zoo

Cov cuab yeej siv tshuab pa

- Ua cov pwm puag ncig, cov cuab yeej siv yog tungsten steel, tungsten steel siab hardness, hnav me me thiab tsim kua muag hauv kev siv, muaj peev xwm txiav, tab sis nkig zoo nkauj, tsis yooj yim.

- Feem ntau yog siv rau kev xuas nrig ntaus, kab noj hniav thiab lwm qhov chaw ua haujlwm.

CNC tshuab cuab yeej

- Roughing pwm. Siv tungsten carbide cutter, siv cov roj emulsified kom txias.

- Thaum txiav, kho tag nrho cov cuab yeej (counterblade)

Kev tsim khoom thiab kev sib dhos

Kev sib dhos txheej txheem ntawm lub twj tso kua mis core

Piston pas nrig, caij nplooj ntoos hlav, me me piston, piston lub rooj, npog, valve phaj, twj tso kua mis lub cev.

Kev sib dhos txheej txheem ntawm lub taub hau twj tso kua mis

Check-place-dispensing-press pump core-press pump head.

Kev sib dhos txheej txheem ntawm straw

Pub cov khoom-pwm (pipe txoj kev)-teeb dej siab tswj yeeb nkab txoj kab uas hla-dej txoj kev-qhov hluav taws xob straw.

Kev sib dhos txheej txheem ntawm lub raj mis airless

Ntxiv cov roj silicone rau lub raj mis lub cev-piston-lub xub pwg lub tes tsho-lub raj mis sab nraud-kuaj cua nruj.

Khoom siv tes ua txheej txheem

Txau

Siv ib txheej ntawm cov xim sib npaug ntawm qhov chaw ntawm cov khoom kom ua tiav cov txiaj ntsig xav tau.

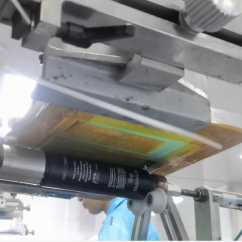

Screen luam ntawv

Luam tawm ntawm qhov screen los ua ib daim duab.

Kub stamping

Sau cov ntawv thiab cov qauv ntawm cov ntawv kub stamping nyob rau hauv qhov kub thiab txias.

Kev sau npe

Siv lub tshuab los sau lub raj mis.

Cov khoom kuaj zoo

Kev tshuaj xyuas

Cov khoom nyoos

Ntau lawm

Ntim

Cov khoom tiav

Cov qauv tshuaj ntsuam xyuas

➽Torque test: Torque = threadprofile inch / 2 (tsim nyog nyob rau hauv qhov ntau ntawm ntxiv lossis rho tawm 1)

➽Kev ntsuas viscosity: CP (unit), qhov tuab ntawm cov cuab yeej xeem yog, qhov me me, thiab qhov nyias nyias ntawm cov cuab yeej xeem, qhov loj dua.

➽Kev kuaj ob xim teeb: thoob ntiaj teb xim daim npav daws teeb meem, kev lag luam cov teeb pom kev zoo D65

➽Optical duab kuaj: Piv txwv li, yog tias qhov kev ntsuam xyuas ntawm lub dome tshaj 0.05 hli, nws yog ib qho tsis ua hauj lwm, uas yog, deformation los yog tsis sib xws phab ntsa thickness.

➽Soj ntsuam: Tus qauv yog nyob rau hauv 0.3mm.

➽Cov menyuam xeem: 1 khoom + 4 ntsia hlau kuaj, tsis muaj daim ntawv poob.

➽Kev ntsuas kub thiab qis: Kev ntsuas kub siab yog 50 degrees, qhov ntsuas kub qis yog -15 degrees, qhov ntsuas av noo yog 30-80 degrees, thiab lub sijhawm kuaj yog 48 teev.

➽Abrasion resistance test: Tus qauv xeem yog 30 zaug hauv ib feeb, 40 rov qab thiab rov qab kev sib txhuam, thiab qhov hnyav ntawm 500g.

➽Kev kuaj Hardness: Tsuas yog cov ntawv gaskets tuaj yeem kuaj tau, chav tsev yog HC, lwm cov pwm tawv tawv muaj cov qauv thiab kev soj ntsuam.

➽Kev ntsuas huab cua tiv thaiv ultraviolet: Txhawm rau ntsuas kev laus, feem ntau pom cov xim tsis zoo thiab cov txheej txheem ua kom tawg. 24 teev ntawm kev sim yog sib npaug rau 2 xyoos nyob rau hauv ib puag ncig ib puag ncig.