Iyo yepurasitiki yekurongedza zvinhu zvekuumba maitiro muindasitiri yezvizorwa inonyanya kukamurwa kuita mapoka maviri: jekiseni kuumba uye kuvhuvhuta.

Jekiseni Molding

Chii chinonzi jekiseni molding process?

Injection molding inzira yekupisa uye kuisa plastiki mupurasitiki (kupisa uye kunyunguduka mumvura, plastiki), uye wozoisa kumanikidza kuipinza munzvimbo yakavharwa mold, ichibvumira kuti itonhore uye isimbise muforogo, kuti ibudise chigadzirwa chine chimiro chakafanana nehombe. Inokodzera kugadzirwa kwakawanda kwezvikamu zvine maumbirwo akaoma.

Hunhu hwekuita jekiseni molding process:

1. Kukurumidza kugadzirwa kwekukurumidza, kushanda kwepamusoro, dhigirii yepamusoro yekushanda automation

2. Chigadzirwa chacho chine hupamhi hwepamusoro, uye kukanganisa kwekuonekwa kuduku zvikuru

3. Kukwanisa kugadzira zvikamu zvine maumbirwo akaoma

4. High mold cost

Zvizhinji zvedubhodhoro risina mweya, double-wall lotion bhodhorozvinogadzirwa nekuita jekiseni.

Kuvhuvhuta kuumba

Hunhu hwe blow molding process:

Kudhirowa zvidzidzo kubva kune yechinyakare girazi kuvhuvhuta maitiro, kuvhuvhuta kunoshandisa mweya wakadzvanywa neimwe dzvinyiriro yekupinza uye kutonhodza preform (semi-yakapedzwa tubular epurasitiki muviri) muforoma kuita yekuumba maitiro ezvigadzirwa zvisina mhango. Inokodzera kugadzirwa kwakawanda kwemidziyo yepurasitiki isina hollow.

Ndeapi maitiro eiyo blow molding process?

1. Nyore nzira yekugadzira, yakakwirira kugadzirwa kwekuita uye otomatiki

2. Low dimensional kururama

3. Pane zvimwe zvinorambidzwa pachimiro chechigadzirwa

4. Low mold cost

Zvinoenderana nematanho akasiyana ekugadzira uye maitiro, kuvhuvhuta kuvhuvhuta kunogona kukamurwa kuita mhando nhatu: extrusion kuvhuvhuta, jekiseni kuvhuvhuta, uye jekiseni kutambanudza kuvhuvhuta.

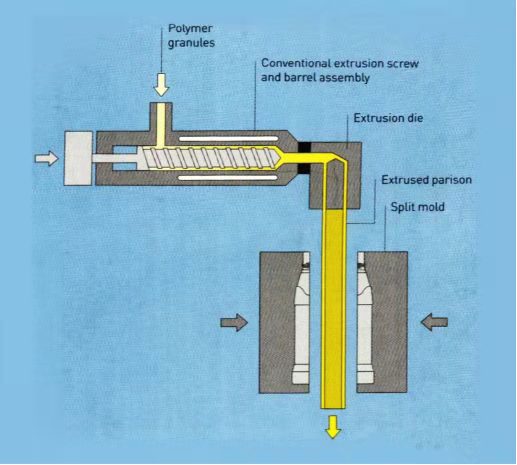

Chekutanga kudzvinya nekufuridza. Sezvinoratidzwa nezita racho, extrusion blow ine matanho maviri makuru: extrusion uye blow molding.

Danho rekutanga ndere extrude parison-mold kuvhara.Iyo extrusion mudziyo unoramba uchitsikitsira kuita gollow tubular parison.Kana iyo parison ichiwedzerwa kune yakafanotemerwa kureba, kumusoro kweparison kunochekwa kusvika pakureba kwakakodzera chidimbu chimwe chete, uye molds kuruboshwe uye kurudyi mativi akavharwa.

Danho rechipiri, mhepo sumo-kucheka.Mhepo yakamanikidzwa inopinzwa mu preform kuburikidza ne mandrel kuti inflate.Iyo parison inonyatso kuomerera kumadziro emukati me mold kuti itonhore uye chimiro, uye chigadzirwa chinobviswa kubva mukuumbwa, uye chechipiri kucheka kunoitwa.Mutengo weextrusion uye kuvhuvhuta michina uye molds wakadzikira, uye mutengo wekugadzira zvakare wakadzikira.

Nekudaro, kupenya kunoitika panguva yekugadzira, uye muromo nepasi pebhodhoro zvinoda kuchekwa nemuchina kana nemaoko, uye dzimwe nguva muromo webhodhoro unoda kukwenenzverwa nekuchekwa.

Extrusion-blow molded epurasitiki mabhodhoro ane mutsara wekuparadzanisa (linear protrusion) pazasi, uye muromo webhodhoro wakashata uye hauna kutsvedzerera, saka vamwe vane njodzi yekudonha kwemvura. Mabhodhoro akadaro anowanzo gadzirwa nePE zvinhu uye anoshandiswa muzvizoro senge mabhodhoro efuro, mafuta ekuzora, shampoos uye maconditioners.

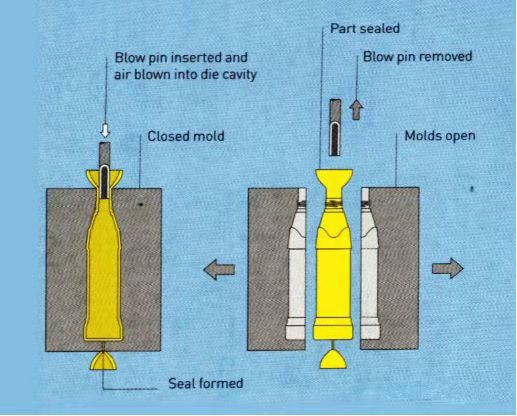

Rudzi rwechipiri nderokuridza jekiseni, rine nhanho huru mbiri: jekiseni-blow molding.

Danho 1: Preform jekiseni-mold kuvhara.

Shandisa jekiseni rekuumba muitiro kuburitsa parison yakadzika, uye koni inotenderera 120 ° kune yekuvhuvhuta yekuumba link.

Iyo mold yakavharwa, uye mweya wakamanikidzwa unopinzwa muprison kuburikidza ne mandrel pores yekuvhuvhuta.

Danho 2: Gadzirira inflation-kutonhora uye kuderedza.

Mushure mekunge chigadzirwa chakaputirwa chanyatsorapwa uye chaumbwa, iyo console inotenderera 120 ° kuburitsa chigadzirwa. Hapana chikonzero chechipiri chekucheka, saka dhigirii re automation uye kugona kwekugadzira kwakakwira. Nekuti bhodhoro rinopeperetswa kubva mujekiseni-yakaumbwa parison, muromo webhodhoro wakapfava uye bhodhoro rine zvisimbiso zviri nani, sengeTB07 inofuridza mabhodhoro akatevedzana.

Rudzi rwechitatu nderekudhonza noti nokufuridza. Yakakamurwa kuita matanho matatu: jekiseni-kutambanudza-kuvhuvhuta kuumba.

Yakasiyana neiyo inotendeuka mhando yekufuridza jekiseni, jekiseni rinotambanudza kuvhuvhuta kugadzirwa kwemutsetse wegungano.

Danho 1: Preform jekiseni-mold kuvhara

Isa preform inogadzirwa nejekiseni mukati mekurova mold

Isa tsvimbo yakatambanudzwa uye uvhare mold kuruboshwe uye kurudyi

Danho rechipiri: Kutambanudza-Kufuridza-Kutonhodza uye kudhiza

Tsvimbo yakatambanudzwa yakatambanudzwa kureba, ukuwo mweya unobaiwa netsvimbo inotatamuka kuti lateral stretching.

Kutonhodza uye kuumba, kudhonzesa uye kubvisa chigadzirwa

Jekiseni rakatambanudzwa kuvhuvhuta ndiyo ine yemhando yepamusoro, chaiyo uye mutengo mukuvhuvhuta maitiro.

Parizvino, kune nzira mbiri dzekugadzira mune jekiseni kutambanudza kuvhuvhuta maitiro, anonzi: imwe-nhanho nzira uye maviri-nhanho nzira. Jekiseni kuumba uye kuumba kuvhuvhuta kunopedzwa pamwe chete nhanho-imwe nzira, uye matanho maviri anopedzwa akazvimirira senzira yenhanho mbiri.

Kuenzaniswa nemaitiro maviri-nhanho, imwe-nhanho nzira inopedzwa mune imwe-nhanho michina kubva kune yakasvibira kusvika kune yakapedzwa chigadzirwa. Nzira yekugadzira iri nyore uye hapana kupisa kwechipiri kunobvumirwa, saka kushandiswa kwesimba kwakaderera.

Iyo-matanho maviri nzira inoda yekutanga preform jekiseni, uyezve yechipiri kugadzirisa pamushini wekuvhuvhuta. Blow molding inoda kudziya kwechipiri kweiyo yakatonhorera preform, saka simba rekushandisa rakakwira.

Ruzhinji rweruzivo rwunobva kuCiE runako rwekupa cheni

Nguva yekutumira: Zvita-29-2021