Isikhokelo soMsebenzi weMveliso kwiTopfeel

Umthamo wokuvelisa umqondiso obalulekileyo kuyo nayiphi na imveliso yokucwangcisa umenzi.

I-Topfeel inkqenkqeza phambili ekuthetheleleni intanda-bulumko yeshishini "yezisombululo zokupakisha izithambiso" ukusombulula iingxaki zabathengi ekukhetheni uhlobo lokupakisha, uyilo, imveliso, kunye nokutshatisa uthotho. Ngokusebenzisa ubuchule obutsha obuqhubekayo kunye nemithombo yokuvelisa umngundo, siye sakuqonda ngokwenene ukudityaniswa komfanekiso webrand yomthengi kunye nengqikelelo yebhrendi.

Uphuhliso lokungunda kunye nokuveliswa

Iimolds zizinto ezahlukeneyo zokubumba kunye nezixhobo ezisetyenziswa kwimveliso yemizi-mveliso yokubumba isitofu, ukubunjwa kokuvuthela, ukukhupha, ukufakela okanye ukubumba ukwenza, ukunyibilikisa, ukunyathela kunye nezinye iindlela zokufumana iimveliso ezifunekayo. Ngamafutshane, ukungunda sisixhobo esisetyenziselwa ukwenza izinto ezimile. Esi sixhobo senziwe ngamacandelo ahlukeneyo, kwaye ukubumba okuhlukeneyo kuyilwe ngamacandelo ahlukeneyo.

Ukuqulunqwa komngundo:

1. I-Cavity: i-polish manual iyadingeka, usebenzisa i-S136 insimbi enobunzima obuphezulu be-42-56.

2. Iziseko zokungunda: ubulukhuni obuphantsi, kulula ukuzikrwempa

3. Inqindi: inxalenye eyenza imilo yebhotile.

4. I-Die core:

① Inxulumene nobomi bomngundo kunye nexesha lemveliso;

②Iimfuno eziphezulu kakhulu ekuchanekeni kwecango

5. Isakhiwo se-Slider: Ukuchithwa kwesobunxele nasekunene, imveliso iya kuba nomgca wokuqhawula, osetyenziswa kakhulu kwiibhotile ezikhethekileyo kunye neengqayi ekunzima ukuzidiliza.

Ezinye izixhobo

Isigrisi

• Ezona zixhobo zichanekileyo kuyo yonke inkqubo yokuvelisa ukungunda.

• Igrinder encinci: iyakwazi ukucubungula ukubumba okujikelezayo kunye nesikwele, sebenzisa utywala bemizi-mveliso ukupholisa phantsi, ukusebenza ngesandla.

• Igrinder enkulu: phatha kuphela i-square molds, ngokukodwa ukuphatha i-angle efanelekileyo yesiseko sokubumba; ukupholisa ioli emulsified; ukusebenza koomatshini.

Drill press

Umatshini wokugaya: ukucubungula umngxuma wesikrufu sokungunda.

Umatshini wokugaya: imingxunya erhabaxa yokwenza isikhonkwane, kwaye unokusika umngundo.

Umatshini wokucofa ozenzekelayo: ukusetyenzwa komsonto wokubumba

①Amazinyo eziko lokujija acocekile

②Ubude bomsonto bulungile

Izixhobo zoomatshini eziqhelekileyo

- Ukucubungula ukubunjwa okujikelezayo, isixhobo esisetyenzisiweyo yintsimbi ye-tungsten, i-tungsten yensimbi ephezulu, i-tungsten igugile kunye nokukrazula ekusebenziseni, ukukwazi ukusika okunamandla, kodwa ukuthungwa okuncinci, ubuthathaka.

- Isetyenziswa kakhulu kwiipuntshi, imingxuma kunye nezinye iindawo ezingqukuva.

Izixhobo zoomatshini be-CNC

- Ukungunda roughing. Sebenzisa i-tungsten carbide cutter, sebenzisa ioli e-emulsified ukupholisa.

-Xa usikwa, lungelelanisa zonke izixhobo (i-counterblade)

Inkqubo yokuvelisa kunye nendibano

Inkqubo yokuhlanganisa ingundoqo yempompo

Intonga yepiston, intwasahlobo, ipiston encinci, isihlalo sepiston, ikhava, ipleyiti yevalvu, umzimba wempompo.

Inkqubo yendibano yentloko yempompo

Khangela-indawo-yokukhupha-cinezela impompo core-press intloko yempompo.

Inkqubo yokuhlanganisa umququ

Ukondla imathiriyeli-umngundo (ukwenziwa kombhobho) -ukuseta umbhobho wokulawula uxinzelelo lwamanzi umbhobho wedayamitha-umzila wamanzi-indiza yokuphuma.

Inkqubo yendibano yebhotile engenamoya

Yongeza ioli ye-silicone kwibhotile yomzimba-piston-igxalaba lomkhono webhotile-ukuvavanya ukuqina komoya.

Inkqubo yemveliso yobugcisa

Ukutshiza

Faka umgca wepeyinti ngokulinganayo phezu komgangatho wemveliso ukufezekisa umphumo oyifunayo.

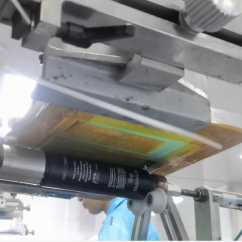

Ushicilelo lwekhusi

Ukuprinta kwiscreen ukwenza umfanekiso.

Isitampu esishushu

Shicilela isicatshulwa kunye neepatheni kwiphepha elitshisayo lokunyathela phantsi kweqondo lokushisa eliphezulu kunye noxinzelelo oluphezulu.

Ukuleyibhile

Sebenzisa umatshini ukubhala iibhotile.

Uvavanyo lomgangatho wemveliso

Inkqubo yokuhlola

Impahla engekasilwa

Imveliso

Ukupakishwa

Iimveliso ezigqityiweyo

Imigangatho yokuhlola

➽Uvavanyo lweTorque: Torque = threadprofile idayamitha/2 (ufanelekile phakathi koluhlu dibanisa okanye thabatha 1)

➽Uvavanyo lwe-viscosity: I-CP (iyunithi), i-test yesixhobo sokuvavanya, incinci, kwaye incinci isixhobo sokuvavanya, sikhulu.

➽Uvavanyo lwesibane esinemibala emibini: Uvavanyo lwesisombululo sekhadi lombala wamazwe ngamazwe, umthombo wokukhanya oqhelekileyo weshishini D65

➽Uvavanyo lomfanekiso obonakalayo: Ngokomzekelo, ukuba umphumo wokuvavanya wedome udlula i-0.05 mm, kukungaphumeleli, oko kukuthi, i-deformation okanye ubukhulu bodonga olungalinganiyo.

➽Uvavanyo lwekhefu: Umgangatho ungaphakathi kwe-0.3mm.

➽Uvavanyo lwe-roller: Imveliso eyi-1 + iimvavanyo ezi-4 zesikrufu, akukho phepha eliwayo.

➽Uvavanyo oluphezulu noluphantsi lobushushu: Uvavanyo oluphezulu lweqondo lokushisa ngama-degrees angama-50, uvavanyo oluphantsi lokushisa luyi-15 degrees, uvavanyo lomswakama luyi-30-80 degrees, kwaye ixesha lokuvavanya iiyure ezingama-48.

➽Uvavanyo lokumelana ne-abrasion:Umgangatho wokuvavanya ngamaxesha angama-30 ngomzuzu, iifrictions ezingama-40 ngasemva naphambili, kunye nomthwalo we-500g.

➽Uvavanyo lokuqina: Kuphela i-gaskets yamaphepha inokuvavanywa, iyunithi yi-HC, ezinye iimbumba ezinobunzima zinemigangatho kunye nenkqubo yokubeka iliso.

➽Uvavanyo lokumelana nemozulu ye-ultraviolet: Ukulinganisa ukuguga, ubukhulu becala ukubona ukuguquka kwebala kunye nenkqubo yokuchithwa. Iiyure ezingama-24 zovavanyo zilingana neminyaka emi-2 phantsi kokusingqongileyo okuqhelekileyo.