Inqubo yokubumba impahla yokupakisha epulasitiki embonini yezimonyo ihlukaniswe ikakhulukazi izigaba ezimbili: ukubumba umjovo kanye nokubunjwa kokushaywa.

Ukubunjwa komjovo

Ithini inqubo yokubumba umjovo?

Ukubunjwa komjovo kuyinqubo yokushisa kanye ne-plasticizing ipulasitiki (ukushisa nokuncibilika ku-fluid, i-plasticity), bese usebenzisa ingcindezi yokuyijova endaweni yokubunjwa evaliwe, okuvumela ukuba kuphole futhi kuqiniswe ekubunjweni, ukukhiqiza umkhiqizo onesimo esifanayo nesikhunta. Ifaneleka ukukhiqizwa ngobuningi bezingxenye ezinobunjwa obuyinkimbinkimbi.

Izici zenqubo yokubumba umjovo:

1. Isivinini sokukhiqiza esisheshayo, ukusebenza kahle okuphezulu, izinga eliphezulu lokuzenzekelayo kokusebenza

2. Umkhiqizo unokunemba okuphezulu, futhi iphutha lokubukeka lincane kakhulu

3. Ikwazi ukukhiqiza izingxenye ezinobunjwa obuyinkimbinkimbi

4. Izindleko zesikhunta eziphezulu

Iningi lethuibhodlela elingenamoya, ibhodlela lolotion elinezindonga ezimbiliakhiqizwa inqubo umjovo.

Vuthela ukubumba

Izici zenqubo yokubumba i-blow:

Izifundo zokudweba ezisuka kunqubo yokuvunguza yengilazi yendabuko, ukubumba kusetshenziswa umoya ocindezelwe onokucindezela okuthile ukuze kugcwale futhi kuphole i-preform (umzimba wepulasitiki we-tubular oqediwe kancane) ekubunjweni kube inqubo yokubumba yemikhiqizo engenalutho. Ilungele ukukhiqizwa ngobuningi kweziqukathi zepulasitiki ezingenalutho.

Yiziphi izici zenqubo yokubumba igalelo?

1. Indlela yokukhiqiza elula, ukusebenza kahle kokukhiqiza okuphezulu kanye ne-automation

2. Ukunemba kwe-dimensional ephansi

3. Kunemikhawulo ethile ekubunjweni komkhiqizo

4. Izindleko zesikhunta eziphansi

Ngokwezinyathelo ezihlukene zokukhiqiza kanye nezinqubo, ukubumba igalelo kungahlukaniswa ngezinhlobo ezintathu: ukuvunguza kwe-extrusion, ukuvunguza komjovo, nokuvunguza okunwebeka komjovo.

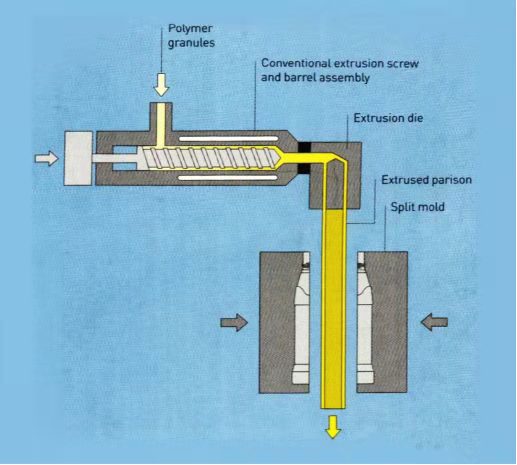

Okokuqala ukukhama nokuphephetha. Njengoba igama liphakamisa, i-extrusion blow inezinyathelo ezimbili ezinkulu: i-extrusion ne-blow molding.

Isinyathelo sokuqala siwukukhipha ukuvalwa kwe-parison-mold.Idivayisi ye-extrusion iyaqhubeka nokumpintsha ukuze yakhe i-parison ye-tubular engenalutho.Lapho i-parison idluliswa ubude obunqunyiwe, phezulu kwe-parison kusikwa ubude obufanele ucezu olulodwa, futhi isikhunta ngakwesobunxele nangakwesokudla sivaliwe.

Isinyathelo sesibili, isingeniso somoya-ukusika.Umoya ocindezelwe ujovwa ku-preform ngokusebenzisa i-mandrel ukuze ugcwale.I-parison inamathela eduze odongeni lwangaphakathi lwesikhunta ukuze lupholile futhi lubumbe, futhi umkhiqizo ukhishwa esikhunjeni, futhi ukusika kwesibili kwenziwa.Izindleko zemishini yokukhipha kanye yokufutha kanye nezibungu ziphansi, futhi izindleko zokukhiqiza nazo ziphansi.

Kodwa-ke, ukucwayiza kwenzeka ngesikhathi sokukhiqiza, futhi umlomo kanye naphansi kwebhodlela kudinga ukusikwa ngomshini noma ngesandla, futhi ngezinye izikhathi umlomo webhodlela udinga ukupholishwa futhi unqunywe.

Amabhodlela epulasitiki abunjwe nge-Extrusion-blow anomugqa wokuhlukanisa (i-linear protrusion) ngezansi, futhi umlomo webhodlela unobushelelezi futhi awubushelelezi, ngakho-ke amanye asengozini yokuvuza uketshezi. Amabhodlela anjalo ngokuvamile enziwe ngezinto ze-PE futhi asetshenziselwa izimonyo ezifana namabhodlela e-foam, amafutha okugcoba umzimba, ama-shampoos kanye nama-conditioner.

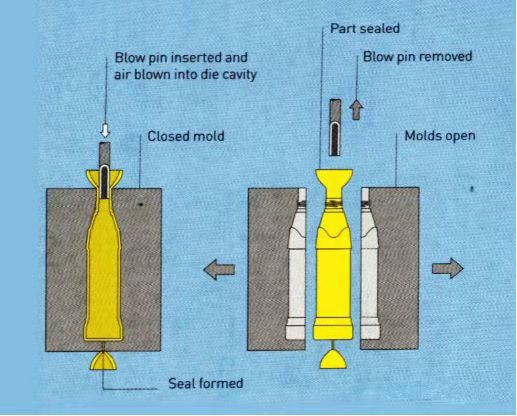

Uhlobo lwesibili ukufutha komjovo, okunezinyathelo ezimbili ezinkulu: ukubumba umjovo wokuvuthela.

Isinyathelo 1: Ukuvalwa kwangaphambili komjovo-isikhunta.

Sebenzisa inqubo yokubumba umjovo ukuze ukhiqize i-parison ephansi, futhi ikhonsoli izungeza ngo-120° kusixhumanisi sokubumba.

Isikhunta sivaliwe, futhi umoya ocindezelweyo ungeniswa egcekeni ngokusebenzisa izimbotshana ze-mandrel zokubumba igalelo.

Isinyathelo sesi-2: Yenza kusengaphambili ukupholisa nokwehliswa kwamandla emali.

Ngemuva kokuthi umkhiqizo owenziwe ngokufutheka usulapheke ngokuphelele futhi ulolongiwe, ikhonsoli izungeza ngo-120° ukuze idilize umkhiqizo. Asikho isidingo sokusikwa kwesibili, ngakho-ke izinga lokuzenzakalelayo nokusebenza kahle kokukhiqiza liphezulu. Ngenxa yokuthi ibhodlela liphephethwa epharishini elibunjwe ngomjovo, umlomo webhodlela uyisicaba futhi ibhodlela linezindawo zokuvala ezingcono, njengeI-TB07 efutha ibhodlela uchungechunge.

Uhlobo lwesithathu ukudonsa nokuphephetha inothi. Ihlukaniswe ngezinyathelo ezintathu: ukubumba umjovo-ukunweba-igalelo.

Okuhlukile ohlotsheni oluphendukayo lomjovo ovunguzayo, ukuvunguza okunwebeka komjovo kuwukukhiqizwa komugqa wokuhlanganisa.

Isinyathelo 1: Ukuvalwa kwangaphambili komjovo-isikhunta

Faka i-preform ekhiqizwe ngomjovo kusikhunta sokushaywa

Faka induku yokwelula bese uvala isikhunta kwesokunxele nakwesokudla

Isinyathelo sesi-2: Ukwelula-Ukuphephetha-Ukupholisa nokudiliza

Induku enwebekayo yeluliwe ngobude, kuyilapho umoya ujovwa ngenduku enwebekayo ukuze yelulwe eceleni.

Ukupholisa nokubumba, ukudiliza nokukhipha umkhiqizo

Ukuvunguza okunwebeka komjovo yikona okunekhwalithi ephezulu kakhulu, ukunemba kanye nezindleko zenqubo yokubumba igalelo.

Njengamanje, kunezindlela ezimbili zokukhiqiza enqubweni yokufutha yokwelula umjovo, ebizwa ngokuthi: indlela yesinyathelo esisodwa kanye nendlela yezinyathelo ezimbili. Ukubumba umjovo kanye nokubunjwa kokushaywa kuqedwa ndawonye ngendlela yesinyathelo esisodwa, futhi izinyathelo ezimbili ziqedwa ngokuzimela njengendlela yezinyathelo ezimbili.

Uma kuqhathaniswa nendlela yezinyathelo ezimbili, indlela yesinyathelo esisodwa igcwaliswa emishinini yesinyathelo esisodwa ukusuka ezintweni ezingavuthiwe ukuya kumkhiqizo ophelile. Inqubo yokukhiqiza ilula futhi akukho ukushisa kwesibili okuvunyelwe, ngakho ukusetshenziswa kwamandla kuphansi.

Indlela yezinyathelo ezimbili idinga umjovo wokuqala we-preform, bese icutshungulwa okwesibili emshinini wokubumba wokushaya. Ukubumba i-Blow kudinga ukushisa kwesibili kwe-preform epholile, ngakho-ke ukusetshenziswa kwamandla kuphezulu.

Ulwazi oluningi luvela ku-CiE beauty supply chain

Isikhathi sokuthumela: Dec-29-2021